By Jimbo Wallace

Unleash The Bavarian Beast – S55 M3 / M4

BMW’s decision to downsize and turbocharge the latest M3/M4 is in line with all of the emissions conscious manufacturers of late, but whereas some have decried the move away from the high-revving, naturally aspirated (some say unreliable!) 4.0 V8 of the E92 M3 the latest turbo’d cars are now capable of making truly obscene leaps in power with the right bolt-on modifications. That’s why Forge now produces some of the finest supporting modifications to truly awake the beast from the within 3.0-litre straight six 3.0-litre turbo lump. The S55 lump in the F80 M3 / M4 is already no slouch, but with the aid of the Forge product line up along with some binary tweaking of the ECU and a free-flowing exhaust setup, it’s usual to see in region of 550 - 600hp from this seriously potent six banger. Of course, additional boost pressure also leads to increased intake temps and the associated reduction in life-giving, chilled compressed air to the inlet manifold. To remedy this as the turbo starts to work harder, we’ve developed a slew of products to keep things as chilled as Buddha on a two-week all-inclusive in Bali. Such Zen like cooling ability comes from years of engineering experience from within the R+D department at Forge HQ, so with some faith in the men in white coats, it’s possible pickup extra horsepower by drastically increasing intake air efficiency.

When really pushing on with the S55 engine be wary that the crank hub bolt is a known weak spot and if it jumps a tooth or fails altogether the car could fall into limp or refuse to start altogether. Crank hub upgrades are now a very common S55 modification, so bear that in mind before going large with BMWs straight six allure and maxing out the revs all the time at higher power levels.

If there’s one area of weakness that the S55 straight six is known for, particularly when upping the boost pressure, it’s the stock chargecooler setup. With such tight engine bay confines and so much plumbing, engine and turbo to account for, under-bonnet temps can easily creep up once the boost goes north and the output begins to climb. To combat such thermal inefficiency, Forge delved deep into water-cooled chargecooler tech and produced that’s more engine bay art than run of the mill aftermarket part. FMCC1 features an all aluminium construction which overcomes all the issues relating to plastic end tank splitting, failure at high boost and leaks between the core and end tanks with end tank seal failure. The end tanks are fabricated using high precision laser cut sheet metal panels which are TIG welded by hand for maximum strength and durability.

Designed and manufactured at Forge Motorsport HQ in Gloucestershire, England, we utilised our Solidworks CAD design system to assist in the creation, modification, CFD (Computational Fluid Dynamics) analysis and optimisation of this innovative charge cooler. Three different core constructions were evaluated during the development process. The final design of a bar and plate core far outperformed the other two alternatives. In doing this, the Forge Motorsport development engineers have made a quadruple pass design, allowing the water to flow through four passes of the cooler which improves the cooling efficiency beyond any other products currently on the market.

Offering over a 71% increase in volume and over 42% increase of frontal area, in hot climate testing, constant dyno runs showed significantly lower inlet temperatures compared with the stock system and an increase in power of up to 20BHP.

£1798.80

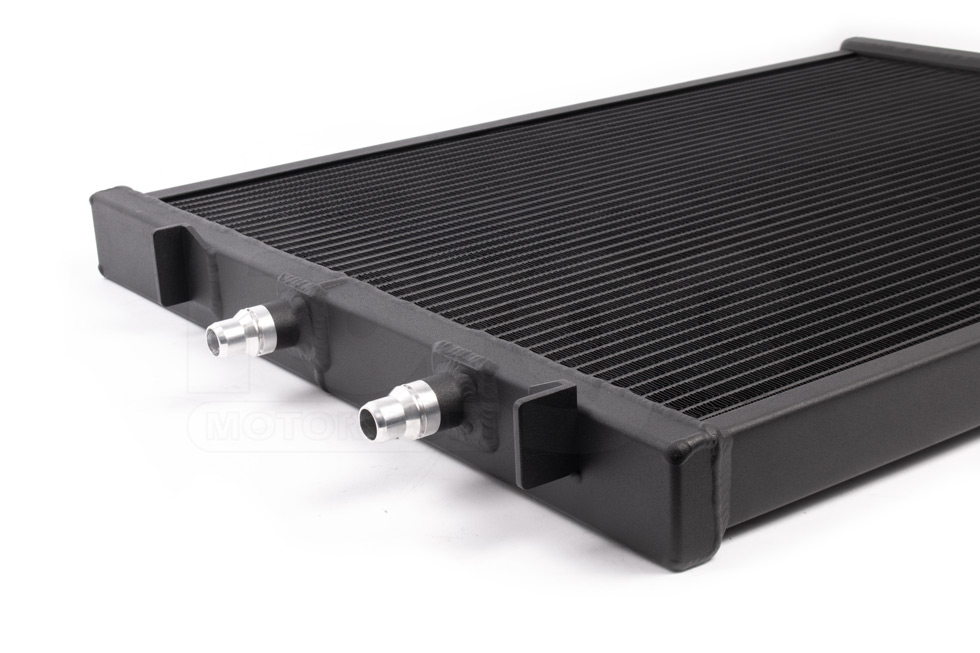

To be used in conjunction with the Chargecooler and expansion tank upgrade (above), or as a standalone cooling upgrade, the auxiliary Polarcooler radiator for the M3 / M4 helps to reduce coolant temps further still. Building on lessons learnt when developing our successful range of Audi and Mercedes charge cooler system upgrades, Forge has now designed this uprated charge cooler rad to gain maximum air flow thanks to a significant increase in both surface area and internal volume. With an internal capacity of upto 1.7-litres and a built-in bleed port this upgrade requires no cutting, drilling or adaptation of the chassis or bodywork at all. Measuring in at 545 x 460 x 32mm it’s a no brained upgrade for those seeking to get the very best from their M-powered Beemer.

£719.99

Designed as a direct replacement for the OEM plastic boost pipes used on BMW S55 engine found in the BMW F80 M3, F82 and F83 M4 models, which have been known to fail with cracks forming along the plastic welded section between the main tube and plastic coupler. Manufactured in 60mm diameter Aluminium tube with CNC machined couplers to maximise flow. To ensure an OEM quality fit both hardpipes have been carefully contoured to fit in the restricted space between the engine and chassis. No further modifications are necessary to the bodywork or pipework.

Supplied with a durable black powdercoated finish, all fitting hardware, hardpipes and silicone hoses to allow fitment to both the OEM chargecooler, or the Forge chargecooler, this kit will improve flow and longevity for many years to come.

Compatible Vehicles: BMW M3 – 2015 onwards F80 M3, BMW M4 F82 and the 2015 onwards F83 M4

£482.98

Take a deep breath because this belongs in a gallery, not on your driveway! As Cypress Hill once famously warbled, “Inhale, exhale. Just put an induction kit in the mail.” Or something like that. Anyway, the latest carbon fibre intake from Forge is created from a mould that is hand-finished and refined by one of our many skilled craftsmen at Forge Motorsport’s HQ in Gloucestershire, England. The men in white coats utilised Forge’s Solid works CAD design system to assist in the creation, modification, analysis and optimisation of the high flow application. The Forge Carbon air intake has been designed to improve the engines ability to breathe and to increase performance. Our engineers have looked at every characteristic and made improvements in volume, shape, size of intake and airbox construction, this has all been maximised to contribute in achieving optimum performance and allow the engine to draw in as much air as possible.

The airbox comes manufactured in an autoclave using prepreg carbon fibre, by using this technology on Forge Carbon fibre parts we have made a product that is much lighter and (20-40%) stronger than liquid infusion.

With this unique, sleek design, you can expect to see a carbon fibre housing that flows beautifully along the engine bay, giving you more horsepower and torque, and hopefully an appreciation for the care and time that has gone into the production.

Having spent so much time on the carbon development we then turned to the equally important aspect of filtration. We engaged our technical partners and experts in Filtration Control, Pipercross.

With over 25 years’ experience in both the domestic and motorsport market they recommended a multi-layer foam construction filter, these filters work perfectly in our High Flow range and the brace of filters provided flow 30% more air than the stock filter while fitting snuggly within the housing.

During independent dyno tests we saw impressive gains of 12hp and 20ft/lbs, so the flow characteristics of the new airbox make it the perfect way to enhance and amplify one of Bavaria’s flagship Ulitmate Driving Machines.

£1249.99

Visit our EU Site

Visit our EU Site

Visit our USA Site

Visit our USA Site

Visit our Asia Site

Visit our Asia Site