You’ve seen the Forge Motorsport logo on the front of British Touring Car Champion Tom Ingram’s car, and now you’re wondering, what do Forge do with the cars?

Well, you’re in luck. We’re going to give you a full run down on what we’ve done over the past few years to co-create a championship winning BTCC car!

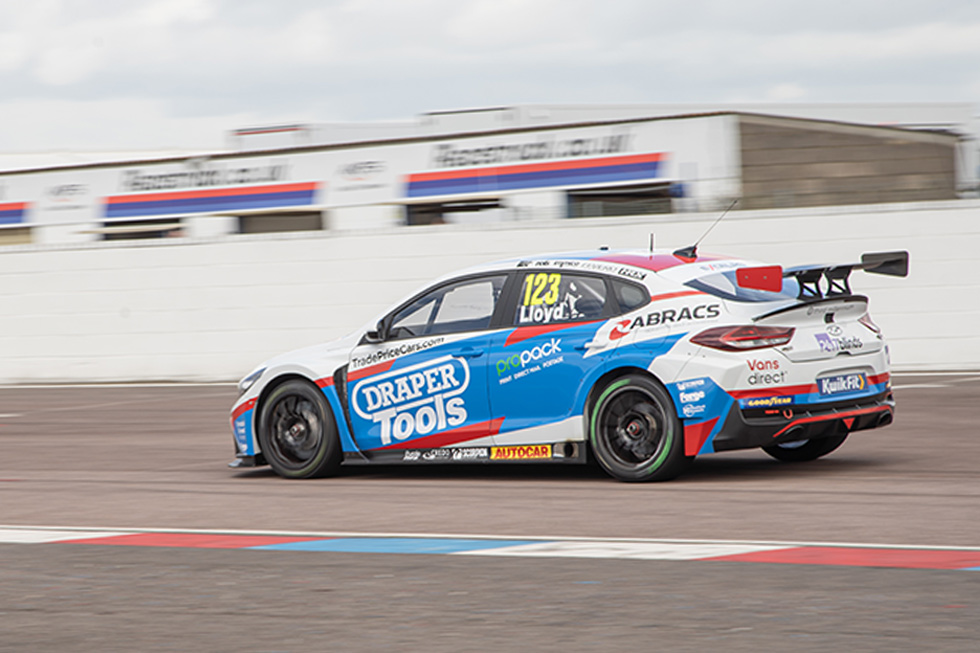

We’ve been within the British Touring Car Championship for a few years now, providing an extensive cooling package for Team Excelr8. Originally, we designed a package for the older MG cars that the team ran, however, in 2021 Excelr8 made the shift to the popular Hyundai i30N chassis, which the 2022 season demonstrated was a championship winning platform.

The Hyundai i30N platform has been incredibly popular for us here at Forge Motorsport, we provide an extensive range of parts, from an intake and turbo elbow to an oil cooler and Intercooler, designed and tested exclusively on track and dyno. Our reputation and association with aftermarket Hyundai products has led the Forge brand into being one of the best in the game in terms of both performance and quality. You can browse our full range of products here on our website.

So, what do we design, engineer, and manufacture for the Team Excelr8 i30N? Well as mentioned the extensive cooling package is what we are behind for the cars! The job of the cooling package is to get these cars running as cold as possible, on the hottest race days, ensuring that they perform at their peak power output throughout the high intensity racing that the cars go through on a typical race weekend.

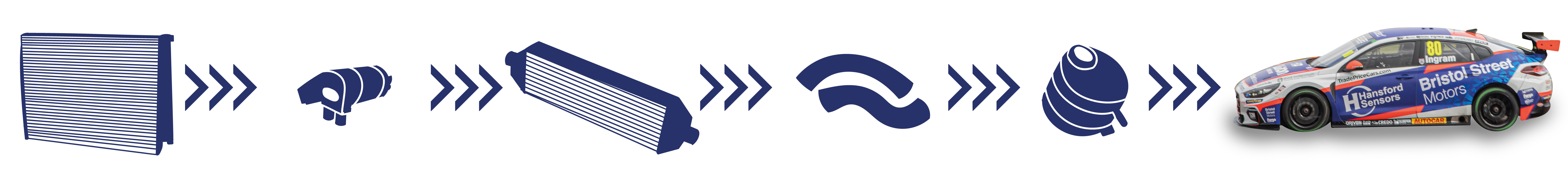

Included in the cooling package, starting with the bigger, more obvious parts that you’d expect from us here at Forge Motorsport, then down to the smaller, lesser-known parts:

Intercooler – Of course, we supply the intercoolers for the team. The homologated air core supplied by BTCC themselves provided us with the challenge of maximising our engineering knowledge to produce the most efficient intercooler possible. We did this through innovative end tank design and clever construction of the boost-tract system. The set-up’s key objective is to provide the coldest air possible for the engine. Colder air means more potential power that we can get the cars producing, so it’s imperative that we create the most efficient intercooler possible. We utilised both our years of experience working on race cars from all disciplines of motorsport, as well as our road going products that are available for many different applications to produce these intercoolers.

Radiator – The water radiator is also designed and manufactured by us, using a specifically tailored core with tried and tested fin configurations, to ensure that we get the water temps to as low as possible whilst the cars are out on track. Keeping the water temps low ensures that the engine stays cool and isn’t subject to any high heat, which can cause premature fatigue or even failure of components.

Boost and Water Pipes – The Intercooler and Radiator need to be linked with the engine, and that’s done through a network of bespoke hard-pipes, silicone hoses, and braided lines. We hand fabricate the hard pipes here at Forge, ensuring every pipe is built to the upmost specification to negate any failures whilst out on track. We also add sensor bungs and AN fittings to these pipes to allow connections between other parts on the car, and to also allow the team to monitor any temperature parameters that they may want data on throughout the car.

Hybrid Water Reservoirs – The new hybrid system has to be cooled as well as the engine in the touring cars, as part of this system we supplied the water reservoirs to the teams specifications that were set out to us. No expert engineering required from us in this area but the incredible fabrication talent that we house at Forge Motorsport was utilised to create/weld up the reservoirs.

Header Tank –The teams’ specifications included a confined area that the header tanks had to fit within. We fabricated and welded the custom tanks to go along with the Radiator and Water Pipes that we supplied for the Water-Cooling System.

Amongst those main areas we also created footplates, Lamanova housing brackets, Catch-Cans, and many other smaller but bespoke brackets for in and around the cars.

What we also must remember is that the Excelr8 team ran 4 cars throughout the 2022 season, meaning 4 sets of everything mentioned above had to be created by the team here at Forge, we also then supply extras of the components, should any unforeseen crash or damage occur to the vehicles. This makes sure that the team have a full replacement set-up, should they need to do a rebuild during a race weekend.

All the engineering design and fabrication work that was provided by Forge Motorsport was rewarded when we saw Driver Number 80 Tom Ingram lift the championship trophy at the season Finale at Brands Hatch. A true testament to the team we have here at Forge and ongoing partnerships that we have within the motorsport and BTCC world.

You can rest easy in the comfort knowing that everything that we learn through our extensive motorsport partnerships, gets reflected in our full range of road-going products that are available to you.

Visit our EU Site

Visit our EU Site

Visit our USA Site

Visit our USA Site

Visit our Asia Site

Visit our Asia Site